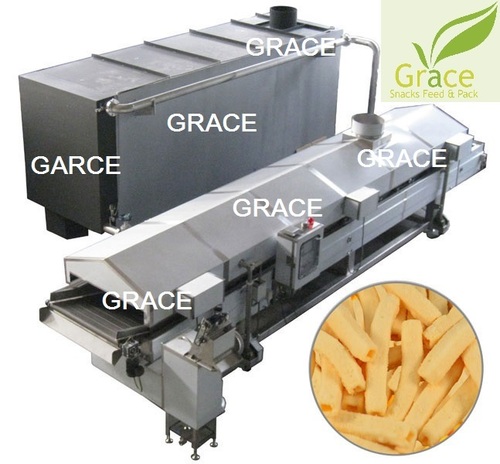

Continous Namkeen Fryer

Product Details:

- Product Type Continous Namkeen Fryer

- General Use Namkeen

- Material Stainless Steel

- Type Food Processors

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Click to View more

X

Continous Namkeen Fryer Price And Quantity

- INR

- 1 Unit

Continous Namkeen Fryer Product Specifications

- Namkeen

- Continous Namkeen Fryer

- Food Processors

- Yes

- Yes

- Stainless Steel

- PLC Control

Continous Namkeen Fryer Trade Information

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 15 Unit Per Month

- 30 Days

- Western Europe Australia North America Eastern Europe Central America Africa Middle East South America Asia

- All India

Product Description

The necessary parts of this Continuous Namkeen Fryer include drum coarse oil filtration section and heat exchanger.

Design Details:

- Equipped with single piece of stainless steel fabricated net conveyor

- Variable frequency drive converter

- Mechanically locked motor controlled screw jacks for lifting its hood

- Drum coarse oil filtering arrangement

- Spray nozzles located in its hood as part of its optional features

- Self regulated oil level controller

- PLC controlled touch screen based operation as optional feature

- Food grade stainless steel structure

- The piping system of this machine has multiple pipes having three meters of gap between each pipe

- The transmission pipe is not made of stainless steel.

- Equipped with 1.5 x 1.5x 12 mtrs conveyor

- F.O.B. New Delhi USD dollar price, Installation, Crating and Tax not included.

Optional :

- Consistent belt filtration method

- Uniform oil circulation arrangement for effective elimination of suspended particles constantly

- The volume of oil goes through its filter to prevent particle deposition

- Accessible in custom made specifications

Features:

- Equipped with uniform oil distribution facility via its heat exchanger, filter and fryer

- The temperature and other parameters of this snacks fryer can be modified as per application needs.

- The special design of its oil inlet maintains smooth and consistent flow of oil to keep its feeding section oil free.

- The submerge conveyor and metering paddles of this frying line minimizes cooking duration.

- Fast oil dispersion method and rapid oil heating mechanism guarantees about crispiness of snacks. Its advanced frying technique prolongs storage life of prepared snacks. This machine is capable of maintaining precise level of oil mechanically.

- The CIP spray nozzles located in its exhaust stack and hood are instrumental in effective removal of accumulated substances in all its parts where oil is circulated. Its circulation system uniformly distributes sodium bicarbonate and water in hard to reach sections during cleaning work.

- The mechanically lockable motor controlled screw jacks are used to lift its paddles, hood and submerged conveyor for trouble free access to its frying bed.

- Touch operated PLC based mechanism and water repellent control box for prolonged service life of its electrical parts

- Overload protected motors

- Both sides are equipped with emergency stop switches.

- Easy to operate mechanism and trouble free maintenance technique

- Pressure switch is used to examine pressure of frying oil inside its pipeline.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Automatic Frying Machine' category

"We mail mainly serve in Gulf Countries and African Countries."

|

GRACE FOOD PROCESSING & PACKAGING MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free Send SMS

Send SMS